Active And Mature Technology Details

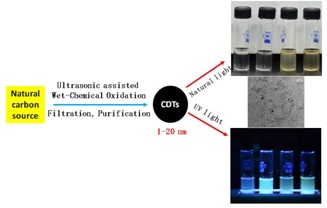

19. Carbon Quantum Dots

1 |

Title of Product/Design/Equipment |

Large scale production of carbon quantum dots (CQDTs) |

2 |

IPR Status |

Patent filed in India and abroad: Indian Application No. IN 201711007354; US Application No. US 15/704,364. |

3 |

Application/Uses |

Efficient, large scale production, and simple synthesis of high-value carbon dots |

4 |

Salient Technical Features including competing Features |

High impact materials like carbon dots (CDTs), are newly rising carbon nanomaterials (CNMs) amongst the nanocarbon member and progressively it is turning into a rising star. Carbon dots are in general consisting of carbon nanoparticle of less than 10 nm in size termed as carbon quantum dots (CQDTs) and graphene nanosheets with a plane size much less than 100nm termed as graphene quantum dots (GQDTs). CQDTs have a broad range of application in extraordinary fields such as biosensing, bioimaging, drug delivery, photocatalysis, photovoltaic devices, and optoelectronics. Compared to traditional semiconductor quantum dots, the unique characteristics of the CQDTs are low toxicity, biocompatibility, low cost, chemical inertness, and similar fluorescence properties. We have a lab-scale process for the preparation of carbon dots which uses novel ultrasonic-assisted wet-chemical method with environmental control. The method also overcomes the above-mentioned drawbacks such as it is less time consuming, minimum amount of water and ammonia solution is needed for the neutralization step and additional experimental steps are not required to enhance the yield of the product. |

5 |

Level/Scale of Development |

TRL5 |

6 |

Environmental Considerations |

NA |

7 |

Status of Commercialization |

Ready for commercialization |

8 |

Major Raw Materials to be utilized |

Low-grade coals; Water etc. |

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

As per NEIST technology package |

11 |

Technology Package |

Patented technology |

12 |

Contact Details |

Director, |

13 |

Photograph |

|

18. Extraction and Separation of Oxyresveratrol Technology

1 |

Title of Product/Design/Equipment |

Extraction and Separation of Oxyresveratrol |

2 |

IPR Status |

Patent No. WO 2016056029 A1 |

3 |

Application/Uses |

The product has strong antiglycation and antioxidant activities. It can be used as vermifuge for treatment of tape-worm infestation. It has anti-aging, cardioprotective and anticancerous properties. The product has strong antioxidant activity. The product has marked anthelmintic effect than standard drugs and has neuroprotective effects against neurodegeneration in Alzheimer's disease. |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

2 kg /batch |

6 |

Environmental Considerations |

Eco-friendly |

7 |

Status of Commercialization |

Ready for commercialization |

8 |

Major Raw Materials to be utilized |

Plant material |

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

Break Even point 21.78 |

11 |

Technology Package |

Ready |

12 |

Contact Details |

Director, |

13 |

Photograph |

|

17. Modular Bricks from Brahmaputra River Bed Sand

1 |

Title of Product/Design/Equipment |

Modular Bricks from Brahmaputra River Bed Sand |

2 |

IPR Status |

- |

3 |

Application/Uses |

Construction of buildings, boundary wall, foundation etc. |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Small scale / Medium scale / Large scale |

6 |

Environmental Considerations |

|

7 |

Status of Commercialization |

Ready for commercialization |

8 |

Major Raw Materials to be utilized |

Brahmaputra River bed sand |

9 |

Major Plant Equipment and Machinery Required |

Modular brick making machine |

10 |

Techno-Economics |

Less production cost than traditional burn clay bricks |

11 |

Technology Package |

Small scale / Medium scale / Large scale |

12 |

Contact Details |

Director, |

13 |

Photograph |

|

16. Technology for extraction of Banana Fibre

1 |

Title of Product/Design/Equipment |

Technology for extraction of Banana Fibre |

2 |

IPR Status |

- |

3 |

Application/Uses |

Manufacture of fabrics, decorative handicraft items, twines & ropes, bristles for brushes, cushions etc |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Eco friendly |

7 |

Status of Commercialization |

Commercialized to 6 parties |

8 |

Major Raw Materials to be utilized |

Banana pseudostem |

9 |

Major Plant Equipment and Machinery Required |

Respodar machine, Rotary digester |

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

15. Technology for production of Low Dust Chalk Pencil

1 |

Title of Product/Design/Equipment |

Technology for production of Low Dust Chalk Pencil |

2 |

IPR Status |

- |

3 |

Application/Uses |

writing on black boards in educational institutions and other demonstration houses. |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Free from white dust |

7 |

Status of Commercialization |

Commercialized to 43 parties |

8 |

Major Raw Materials to be utilized |

|

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF LOW DUST CHALK PENCIL |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

14. Technology for production of Liquid Deodorant Cleaner

1 |

Title of Product/Design/Equipment |

Technology for production of Liquid Deodorant Cleaner |

2 |

IPR Status |

- |

3 |

Application/Uses |

Cleaning of floors & titles, bathrooms, toilets, polishing glass & ceramic articles etc. |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Eco friendly |

7 |

Status of Commercialization |

Commercialized to 45 parties |

8 |

Major Raw Materials to be utilized |

Wax, Plasticizer, emulsifying agent, oil, surfactant |

9 |

Major Plant Equipment and Machinery Required |

Emulsifier machine, Hot plate, Reactor, Electronic balance |

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF LIQUID DEODORANT CLEANER |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

13. Technology for production of Wood Care

1 |

Title of Product/Design/Equipment |

Technology for production of Wood Care |

2 |

IPR Status |

1 publication |

3 |

Application/Uses |

Enhance the durability and strength of bamboo and wood & wood /bamboo products |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Eco friendly product |

7 |

Status of Commercialization |

Ready for commercialization |

8 |

Major Raw Materials to be utilized |

|

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF WOOD CARE FORMULATION : |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

12. Technology for production of Wax Crayon Pencil

1 |

Title of Product/Design/Equipment |

Technology for production of Wax Crayon Pencil |

2 |

IPR Status |

- |

3 |

Application/Uses |

Colour pencil |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Eco friendly |

7 |

Status of Commercialization |

Commercialized to 2 parties |

8 |

Major Raw Materials to be utilized |

|

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF WAX CRAYON PENCIL: |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

11. Technology for production of Handmade Paper

1 |

Title of Product/Design/Equipment |

Technology for production of Handmade Paper |

2 |

IPR Status Patent/Copyright/Trademark secured in Indian/Abroad IPR Details |

- |

3 |

Application/Uses |

file boards, book binding boards etc |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Eco friendly |

7 |

Status of Commercialization |

Commercialized to 3 parties |

8 |

Major Raw Materials to be utilized |

|

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

10. Technology for production of Solid Dispersible Deodorant

1 |

Title of Product/Design/Equipment |

Technology for production of Solid Dispersible Deodorant |

2 |

IPR Status |

- |

3 |

Application/Uses |

Cleaning the floor, tiles, table top & to be use as germ killer, freshener & mosquito repellent. |

4 |

Salient Technical Features including competing Features |

|

5 |

Level/Scale of Development |

Commercial scale |

6 |

Environmental Considerations |

Eco friendly |

7 |

Status of Commercialization |

Ready to commercialization |

8 |

Major Raw Materials to be utilized |

|

9 |

Major Plant Equipment and Machinery Required |

|

10 |

Techno-Economics |

COST ECONOMICS FOR PRODUCTION OF |

11 |

Technology Package |

Rs. 50,000.00 |

12 |

Contact Details |

|

13 |

Photograph |

|

9. Process for the preparation of 4-(4-hydroxyphenyl)butan-2-one from phenol and 4-hydroxybutan-2-one using solid acid clay catalyst (based on nanoporous montmorillonite)

1 |

Title of Product |

Process for the preparation of 4-(4-hydroxyphenyl)butan-2-one from phenol and 4-hydroxybutan-2-one using solid acid clay catalyst (based on nanoporous montmorillonite) |

2 |

IPR status |

Patents: (i) GB 2470338, Grant date. 13.03.2013, (ii) US 8471068, Grant date. 25/06/2013, (iii) CA 2719274, Grant date. 29/12/2015 and (iv) Indian Patent Application No.: 0772DEL2008 (Date of filing 26 March 2008) |

3 |

Application/uses |

Heterogeneous Catalyst for fine chemical synthesis and surface active adsorbents |

4 |

Salient Technical features including competeing features |

Nanoporous clay having high surface area ( > 400 m2/g), high porosity (∼ 80 Å} and surface acidity (∼ 0.6 mmol/g) |

5 |

Level/scale of development |

10 gm Batch Process |

6 |

Environmental consideration |

Environmentally friendly |

7 |

Status of commercialization |

Not yet |

8 |

Major raw materials to be used |

Montmorillonite clay |

9 |

Major plant equipment and machinery required |

Acid digesting vessel, Centrifuge/Filtration unit and dryer |

10 |

Techno-economics |

Not yet estimated |

11 |

Technology package |

Laboratory Scale process |

12 |

Contact details |

Director, CSIR-NEIST, Jorhat 705006, Assam. Phone No: + 91 376- 2370012 |

13 |

Photograph |

No |

9. Mixed Metal Hydroxide based Clay Viscofier

1. |

Title of Product/Design/Equipment |

Mixed Metal Hydroxide based Clay Viscofier |

2. |

IPR Status |

IPR covered both in India and abroad

|

3. |

Application/Uses |

In the formulation of Drilling Fluids for drilling high temperature wells with high salinity especially in the horizontal drilling technology sector for crude liquid and gaseous hydrocarbon exploration |

4. |

Salient Technical Features including |

|

5. |

Level/Scale of Development |

100kg/batch/day scale Pilot Study completed |

6. |

Environmental Considerations |

Environmntalyy Benign and No adverse Affect in Human Health |

7. |

Status of Commercialization |

Looking for Manufacturers |

8. |

Major Raw Materials to be Utilized |

Magnesium Chloride Hydrated, Aluminum Chloride Hydrated, Sodium Hydroxide,Sodium Carbonate |

9. |

Major Plant, Equipment and Machinery Required |

Different Mixing Vessels and Charge Tanks, Basket Centrifuge, Steam Jacketed Glass Line Reactor, Dryer |

10. |

Techno-Economics |

Cost of production per Kg Rs 150.00 |

11. |

Technology Package |

Can be handed over to prospective enterprenures either at lab scale or at turn key level in desired output demand |

12. |

Contact Details |

|

13. |

Photograph |

|

7. CSEB Bricks from stone dust.

1. |

Title of Product/Design/Equipment |

CSEB Bricks from stone dust. |

2. |

IPR Status |

XXXX |

3. |

Application/Uses |

The Compressed Stabilised Earth Blocks (CSEB) can be used for external and boundary walls, interior/ partition wall, pavers, affordable buildings and construction of earth home. |

4. |

Salient Technical Features including |

Low energy, Uniform size, Cost effective, Useful to build residential and community buildings in both urban and rural area,Aesthetic look, Waste utilization,Free from polution |

5. |

Level/Scale of Development |

Pilot Scale Study completed |

6. |

Environmental Considerations |

Environmentaly benign and have no adverse affect to human health |

7. |

Status of Commercialization |

Ready for Commercialisaton |

8. |

Major Raw Materials to be Utilized |

Raw materials used are : |

9. |

Major Plant, Equipment and Machinery Required |

Depending upon the entrepreneurs plant capacity, either a hand operated semi- mechanised brick making machine or an electrically driven fully automatic brick making machine will be used including concrete mixture, curing chamber, water pump, weghing balance etc., electrical fitting and lighting |

10. |

Techno-Economics |

To be calculated as per the entreprenures requirement and production capacity. |

11. |

Technology Package |

Ready |

12. |

Contact Details |

DIRECTOR, NORTH EAST INSTITUTE OF SCIENCE & TECHNOLOGY, (Formerly RRL, Jorhat) |

13. |

Photograph |

|

6. Hydroxy Alumina – A Versatile Inorganic Oligomer

1. |

Title of Product/Design/Equipment |

Hydroxy Alumina – A Versatile Inorganic Oligomer |

2. |

IPR Status |

IPR covered in India |

3. |

Application/Uses |

The Compound is a versatile Inorganic Compound having multiple uses like –

|

4. |

Salient Technical Features including |

The CSIR-NEIST technology does not produce any bye product and gives the product in concentrated form |

5. |

Level/Scale of Development |

Preparation Hydroxy Alumina batch wise in Pilot Level to prepare in 50 KL has been completed |

6. |

Environmental Considerations |

Environmentaly benign and no adverse affect in human health |

7. |

Status of Commercialization |

Looking for Manufacturers |

8. |

Major Raw Materials to be Utilized |

Aluminum Chloride Hydrated, Aluminium Powder, Sodium Carbonate |

9. |

Major Plant, Equipment and Machinery Required |

Different Mixing Vessels and Charge Tanks, Basket Centrifuge, Steam Jacketed Glass Line Reactor, Dryer |

10. |

Techno-Economics |

Poduct is obtained as a concentrated form which is good for transportation |

11. |

Technology Package |

Can be provided at bench scale level to any pfrospective enterprenure |

12. |

Contact Details |

|

13. |

Photograph |

|

5. Herbal Drug for management of Arthritis (Anti-Arthritis)

1. |

Title of Product/Design/Equipment |

Herbal Drug for management of Arthritis (Anti-Arthritis) |

2. |

IPR Status |

Nil |

3. |

Application/Uses |

Ointment for external use on affected parts of the arthritic patients |

4. |

Salient Technical features including Competing Features |

|

5. |

Level/Scale of Development |

Developed at commercial scale |

6. |

Environmental Consideration |

Raw materials are of plant origin and cultivated, so can be procured from market. |

7. |

Status of Commercialization |

Ready for commercialization. |

8. |

Major Raw material to be utilized |

Essential oils of different plant species. |

9. |

Major plant equipment and Machinery required |

Ointment tube filling and sealing machine |

10. |

Techno-Economics |

Economically viable |

11. |

Technology Package |

In preparation |

12. |

Contact Details |

Director |

13. |

Photograph |

|

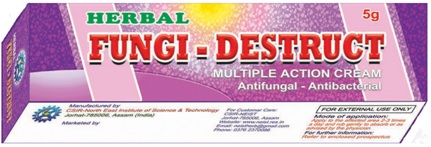

4. Herbal Anti-Fungal Drug for skin infection (Anti-Fungal)

1. |

Title of Product/Design/Equipment |

Herbal Anti-Fungal Drug for skin infection (Anti-Fungal) |

2. |

IPR Status |

Patent No. 0650DEL2007 (Date of Filling: 23/03/2007), Filed in India |

3. |

Application/Uses |

Ointment for external use on fungal and bacterial skin infection |

4. |

Salient Technical features including Competing Features |

|

5. |

Level/Scale of Development |

Developed at commercial scale |

6. |

Environmental Consideration |

Raw materials are of plant origin and cultivated, so can be procured from market. |

7. |

Status of Commercialization |

Ready for commercialization. |

8. |

Major Raw material to be utilized |

Essential oils of different plant species. |

9. |

Major plant equipment and Machinery required |

Ointment tube filling and sealing machine |

10. |

Techno-Economics |

Economically viable |

11. |

Technology Package |

In preparation |

12. |

Contact Details |

Director |

13. |

Photograph |

|

3. Mosquito Repellent Herbal Incense sticks

1 |

Title of Product/Design/Equipment |

Mosquito Repellent Herbal Incense sticks |

2. |

IPR Status |

Patent No. 0455DEL2009 (Date of Filling: 09/03/2009), Filed in India |

3. |

Application/Uses |

To repel mosquitoes from house |

4. |

Salient Technical features including Competing Features |

|

5. |

Level/Scale of Development |

Developed at commercial scale |

6. |

Environmental Consideration |

Raw materials are of plant origin. |

7. |

Status of Commercialization |

Transfer to four parties. |

8. |

Major Raw material to be utilized |

Ground powder of over-ground plant of different plant species |

9. |

Major plant equipment and Machinery required |

Grinder, sets of agarbatti making machines |

10. |

Techno-Economics |

Economically viable |

11. |

Technology Package |

Already prepared |

12. |

Contact Details |

Director |

13. |

Photograph |

|

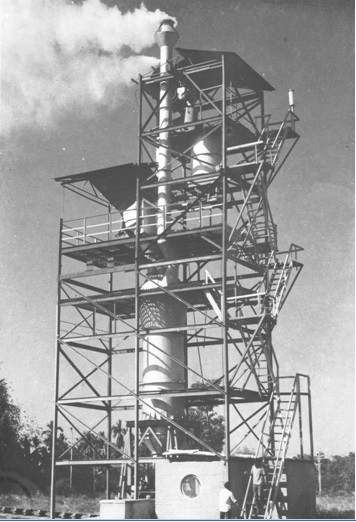

2. Vertical Shaft Kiln Mini Cement Plant

Title of Product/Design/Equipment |

Vertical Shaft Kiln Mini Cement Plant (VSK MCP) |

|

IPR Status |

Patent No. 150483 dated 1979 in India |

|

Application/Uses |

Production of Ordinary Portland Cement (OPC) to BIS specifications (BIS-269), for use in the construction industry. |

|

Salient Technical Features Including Competing Features |

Essentially, the vertical shaft kiln constitutes the heart of the cement plant for the production of quality OPC to BIS specifications in various capacities up to 100 TPD, employing either a single kiln or multiple kilns. As a rule, the VSK is made up of a static vertical shaft lined internally with refractory bricks. Integrated within the kiln is a chimney, a raw-meal feeding inlet, a rotary grate with provision for entry of combustion air, a material block tube and discharge mechanism.

|

|

5. |

Level/scale of development |

Production of OPC to BIS specification by single kiln of capacity 25 TPD, 50 TPD, 100 TPD and multiples thereof. |

6. |

Environmental Considerations |

Owing to the method of manufacture and pollution abatement features adapted at various stages of manufacture, the overall cement-manufacturing process employing VSK MCP technology comply with acceptable national pollution standards. |

7. |

Status of commercialization |

Till date, 39 VSK mini cement plants of different capacities have been set up throughout the country. |

8. |

Major Raw Materials to be Utilized |

|

9. |

Major plant equipment and machinery required |

Apart from the VS Kiln, the following equipments and facilities are required :

|

10. |

Techno-economics |

TENTATIVE PROJECT COST (under Indian condition) : 16,500 TPA 6.00 |

11. |

Technology package |

Detailed Project Reports and TEFRs can be prepared for interested clients for proposed locations. |

12. |

Contact details |

Director, CSIR-NEIST |

13 |

Photograph |

|

1. TP16 Biofertiliser

1 |

Title of the Product/Design/ Equipment |

TP16 Biofertiliser |

2 |

IPR status |

Nil |

3 |

Application/Uses |

Agriculture. |

4 |

Salient Technical features including competing features |

The product is the carrier base microbial formulation name TP16 Biofertiliser. The application of the bio-fertilizer TP16 reduces the amount of use of synthetic nitrogen urea by half the amount keeping intact the plant growth and harvest index of rice and fresh leaf yield in plantation crops tea. The secondary metabolites hormone, antibiotic and mineral solubilisation capacity of TP16 suppresses the deleterious effect plants caused by several minor and major fungal and bacterial plant pathogens. Likewise, the mineral solubilisation capacity of TP16; enhances the nutrient mobilisation of plants and its use efficiency of the plants. As a result the use of this product has multiple benefits in reducing the cost of economics to environmental issues arising out of synthetic agrochemicals. |

5 |

Level/Scale of development |

560 L/ day |

6 |

Environmental Considerations |

Eco-friendly |

7 |

Status of Commercialization |

Successfully commissioned at Duliajan. Properietor : Amrit Organic, Tinsukia, Assam |

8 |

Major Raw Material To be used |

Cheap natully raw material used for cultivation of Microbes. |

9 |

Major Plant Equipment & Machinery Required |

Fermeneter of 670 L Capacity; Mixer. |

10 |

Techno- Economics |

Break even point is 23%. |

11 |

Technology Package |

Ready |

12 |

Contact Details |

Director, CSIR-NEIST, Jorhat 705006, Assam. Phone No: + 91 376- 2370012 |

13 |

Photograph |

|