Extraction and Separation of Oxyresveratrol Technology

The product has strong antiglycation and antioxidant activities. It can be used as vermifuge for treatment of tape-worm infestation.

It has anti-aging, cardioprotective and anticancerous properties. The product has strong antioxidant activity. The product has marked anthelmintic effect than standard drugs and has neuroprotective effects against neurodegeneration in Alzheimer's disease.

It has anti-aging, cardioprotective and anticancerous properties. The product has strong antioxidant activity. The product has marked anthelmintic effect than standard drugs and has neuroprotective effects against neurodegeneration in Alzheimer's disease.

The solvent used for extraction of oxyresveratrol from natural plant is a green solvent. Extractant comes out from the membrane cell can be reused, no generation of toxic chemicals in the process, process is cost effective. Usability of the membrane is up to 15 batch. The process gives 10 g pure product (cost US$ 110.8 = Rs. 6868/-) from 100 g raw material (cost Rs 500/-). The cost is » 14 times greater than raw material cost. The compound has great impact in world market of drug and pharmaceuticals, phytochemicals and Fine chemicals industries. The cost of 99% pure compound is US$ 9980 per kg (Rs. 6.19Lakhs). The cost of crude extract is US$ 10-100 per kg.

Coal beneficiation (de-sulfurization and de-ashing) by using low energy ultrasonication

The low ultrasonic energy (20-40 KHz) was satisfactorily used to clean some low rank medium to high sulfur coal samples from northeast India in lab-scale level and the scale-up studies are ongoing in CSIR-NEIST.

The preliminary study showed the considerable removal of all the forms of unwanted sulfur and mineral matters (ash) from the low-grade coals. The thermal profiles of the beneficiated coal revealed their improved quality for use in thermal plants with better combustion efficiency.

The preliminary study showed the considerable removal of all the forms of unwanted sulfur and mineral matters (ash) from the low-grade coals. The thermal profiles of the beneficiated coal revealed their improved quality for use in thermal plants with better combustion efficiency.

Agglomeration of low rank Northeast Indian coal fines with an organic binder for industrial coke-making (Non-recovery type coke oven for NER coals: low S and C-emission)

Approximately 13% (over 1 billion tonnes) of total coal production is currently used by the Steel industry and around 70% of total global steel production is dependent on coal.

The growth of the iron and steel industry all over the world, prime coking coal with adequate properties that yield metallurgical coke is becoming increasingly difficult to obtain. Thus, there is a considerable economic incentive to use coke breeze and or low rank coals instead of coking coals whenever possible. With shortage of good quality coking coal in NER of India, this innovation was made. The low rank coal samples from North Eastern Region (NER) of India could be nodulized and then carbonized in a beehive-type coke oven towards industrial coke-making. Different types of cheap binders and an additive were used to prepare the nodules for increasing their strength and to reduce the emission of sulphur containing gases, respectively. The physical strength of the carbonized nodules are within the range of 376.81-448.84N, which are found to be suitable for their transportation and handling purposes. The produced coke is observed to be suitable for using as a coke-breeze in cement manufacturing and other domestic purposes.

The growth of the iron and steel industry all over the world, prime coking coal with adequate properties that yield metallurgical coke is becoming increasingly difficult to obtain. Thus, there is a considerable economic incentive to use coke breeze and or low rank coals instead of coking coals whenever possible. With shortage of good quality coking coal in NER of India, this innovation was made. The low rank coal samples from North Eastern Region (NER) of India could be nodulized and then carbonized in a beehive-type coke oven towards industrial coke-making. Different types of cheap binders and an additive were used to prepare the nodules for increasing their strength and to reduce the emission of sulphur containing gases, respectively. The physical strength of the carbonized nodules are within the range of 376.81-448.84N, which are found to be suitable for their transportation and handling purposes. The produced coke is observed to be suitable for using as a coke-breeze in cement manufacturing and other domestic purposes.

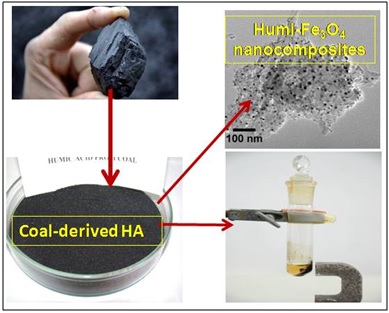

Northeast Indian coal-derived Humic acid (HA) and their Fe3O4-nanocomposites for catalytic application

The inferior grade coal fines and coal waste could be recovered by isolating Humic acid. The possibility of isolating Humic acid from the inferior coal and coal wastes from Northeast Indian coals is established in this institute.

Humic acid is in combination with Humic and Fulvic acids are essential for agriculture. They are also known to be one of the most bio-chemically active materials, which act as soil conditioner. In an another innovative work, Fe3O4 nano-particles supported on coal-derived humic acid was synthesised and tested for the amazing catalytic performance in reduction of hazardous p-nitrophenol. The average diameter of the coal-derived Fe3O4 nanocomposite was about 5-20 nm and it can be recycled for several times without significant loss of its catalytic activity.

Humic acid is in combination with Humic and Fulvic acids are essential for agriculture. They are also known to be one of the most bio-chemically active materials, which act as soil conditioner. In an another innovative work, Fe3O4 nano-particles supported on coal-derived humic acid was synthesised and tested for the amazing catalytic performance in reduction of hazardous p-nitrophenol. The average diameter of the coal-derived Fe3O4 nanocomposite was about 5-20 nm and it can be recycled for several times without significant loss of its catalytic activity.

Coal-derived Carbon Nano-materials (CNMs) by wet-chemical/thermo-chemical methods

The formation of carbon nano-balls and nano-tubes in the clean coal products during wet-chemical as well as thermo-chemical techniques was established by using Scanning Electron Microscopy (SEM),

High Resolution Transmission Electron Microscopy (HR-TEM), X-ray Diffraction (XRD), Raman and Fourier Transform Infrared spectroscopy (FT-IR) analysis The clean coal product (MCL product) consist of carbon nano-balls are in the range of 5-10 nm with nominal areas in the range of 40-100 nm2, 160-220 nm2, and 550-650 nm2. The diameters of the carbon nano-tubes (CNTs) formed were in the range of 18 -24 nm. This is innovation provides the non-fuel as well as an efficient utilization of the low-grade coals for preparation of nano-carbon-based high value added products.

High Resolution Transmission Electron Microscopy (HR-TEM), X-ray Diffraction (XRD), Raman and Fourier Transform Infrared spectroscopy (FT-IR) analysis The clean coal product (MCL product) consist of carbon nano-balls are in the range of 5-10 nm with nominal areas in the range of 40-100 nm2, 160-220 nm2, and 550-650 nm2. The diameters of the carbon nano-tubes (CNTs) formed were in the range of 18 -24 nm. This is innovation provides the non-fuel as well as an efficient utilization of the low-grade coals for preparation of nano-carbon-based high value added products.

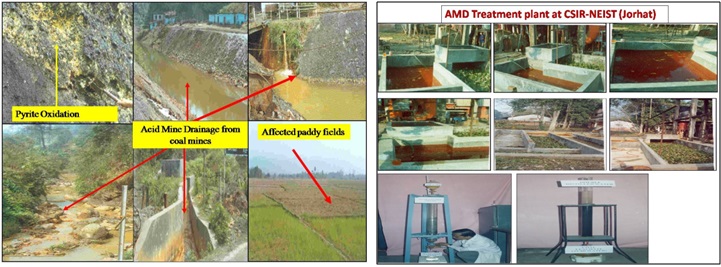

Site specific management of acid mine drainage (AMD) from NER coal mines

With need of the management of AMD in Northeast coalfields, CSIR-NEIST (Jorhat) had developed a site-specific AMD management plant using locally available materials.

During mining of high sulphur coals of the region is formation of Acid Mine Drainage in the effluents discharged from the mines as well as mine rejects dumped in the vicinity of the sites takes place. The cumulative effects of this undermine the assimilative capacity of the eco-systems and degrade the total environmental quality. Alternate processes (chemical and bio-chemical) for management of the problem had been developed. In-situ remediation management processes were also developed.

During mining of high sulphur coals of the region is formation of Acid Mine Drainage in the effluents discharged from the mines as well as mine rejects dumped in the vicinity of the sites takes place. The cumulative effects of this undermine the assimilative capacity of the eco-systems and degrade the total environmental quality. Alternate processes (chemical and bio-chemical) for management of the problem had been developed. In-situ remediation management processes were also developed.

AMD treatment process/technology of CSIR-NEIST (Jorhat):

- Site specific.

- Sequential Alkalinity Leaching Process.

- Scaled up to the pilot plant scale (~500kg/batch).

- Raw materials used are indigenous.

- Less energy consumption.

- Advantage of the process are:

- Does not require electricity.

- Does not require mechanical equipment, hardness chemicals, or buildings.

- Does not require daily operation and maintenance.

- More natural and aesthetic in their appearance and may support plants and wildlife.

- Are less expensive

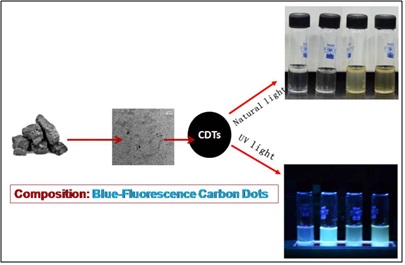

Coal-derived blue-fluorescence emitting Carbon Dots (CDTs)

CSIR-NEIST developed a process for the preparation of blue-fluorescence emitting carbon dots (CDTs) from sub-bituminous tertiary high sulfur Indian coals.

The present invention produced characteristics carbon dots from low-quality Northeast Indian coals by an ultrasonic-assisted wet-chemical method. The method is simple and environmentally benign for fabrication of characteristics and size-controlled carbon dots.

The present invention produced characteristics carbon dots from low-quality Northeast Indian coals by an ultrasonic-assisted wet-chemical method. The method is simple and environmentally benign for fabrication of characteristics and size-controlled carbon dots.

High Strength Proppants

Scientists of the North East Institute of Science and Technology (NEIST) have patented an innovative and economical technology

for hydraulic fracturing operations which could prove to be a boon for the oil and gas industry worldwide.

for hydraulic fracturing operations which could prove to be a boon for the oil and gas industry worldwide.As far as the Indian oil and gas sector is concerned, the knowhow developed in the process of this innovation is the first of its kind in the country.

Ex-Director of CSIR-NEIST, Dr P G Rao, said the development of the process for high strength proppants, used in the extraction of trapped gas and oil from the tertiary layer, will be extremely cost-effective and advantageous for the industry as it uses bauxite, a mineral abundantly available in India.

“As India has abundant high-grade bauxite deposits, the innovation can make the country self-sufficient, and help it take a lead position inthe manufacture of high strength proppants, cutting down on imports.

Oil production activity in the country can be expected to increase manifold in the coming years, vis-à-vis its increased demand.

“The innovation has both a huge market potential, as well as the added advantage of generating more employment avenues,” Rao said.

Explaining the process, Dilip Dutta, former head of general engineering department, CSIR-NEIST, and one of the scientists associated with the innovation, said a “proppant” was a particle baked to such hardness that it could crack the rocky crust of the underground reservoir and release oil and gas.

“The particles are bombarded into the earth crust at the tertiary level with a very strong water jet and this allows for greater recovery of oil and gas after the crust is broken,” Dutta said.

Dutta was responsible for designing the device in which the 2mm bauxite balls (proppants) were made to almost 97 per cent roundness.